QA/QC is not just about sampling and assaying

Quality management is a system that integrates both quality assurance (QA) and quality control (QC) to deliver products and services that consistently meet requirements. Relevant definitions include:

- QA: That part of quality management focused on providing confidence that quality requirements will be fulfilled i.e., the planned and systematic activities in the quality system that provide confidence that a product or service will fulfill requirements for quality.

- QC: That part of quality management focused on the operational techniques and activities used to fulfill requirements for quality.

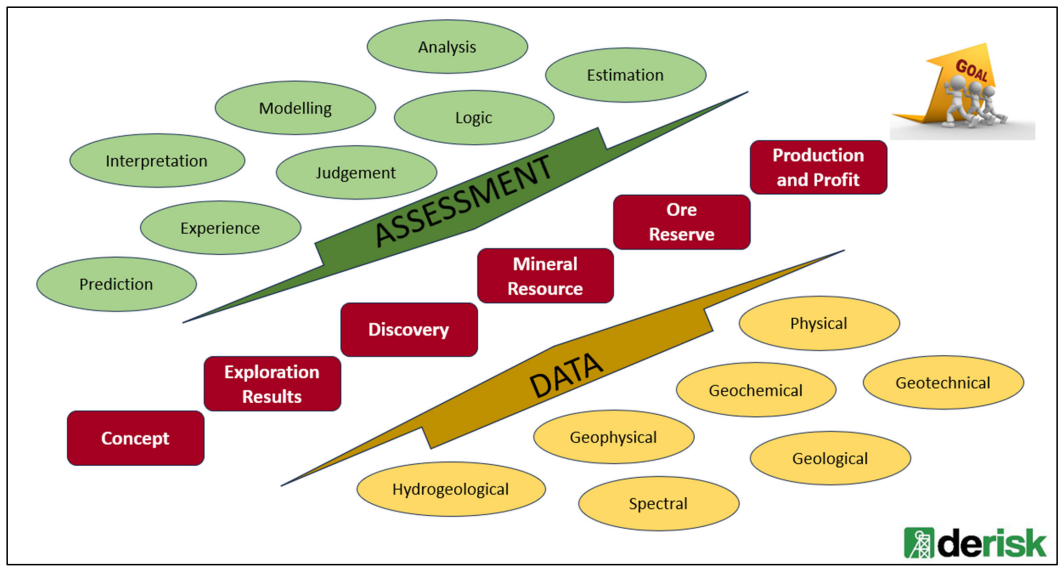

From a minerals industry perspective the key steps moving from exploration to mining involve developing an exploration concept, exploration, discovery, defining Mineral Resources and Ore Reserves, mine development, and ultimately production – all with the goal of achieving a profitable operation.

Geological data collection, assessment, interpretation, and estimation are vital inputs throughout all stages of this cycle. Unfortunately, some technical and management staff consider that geological QA/QC systems and processes are only relevant when addressing drillhole sampling and assaying procedures. This is not so.

The figure below illustrates the various types of geoscientific data that are collected during exploration and mining – together with the various processes used to make use of the data collected. To ensure a high degree of quality management, QA/QC systems are essential across all data collection modes and across all assessment processes that make use of the data.

Since 2017, Derisk has completed many technical reviews of Mineral Resource estimates, and many due diligence reviews of mineral projects at various stages of development. A significant number of these reviews have identified fundamental flaws or serious deficiencies in some of the QA/QC systems required for monitoring the quality of geoscientific data and/or assessment methods.

Some examples of common QA/QC flaws include the following:

- Spatial Data. QA/QC systems to monitor the quality of spatial data such as coordinates of drillhole collars, downhole drillhole survey data, and channel sample locations can be inadequate.

- Density Data. Critical in converting volume estimates to tonnage estimates, many examples have been documented where there is no formal system to monitor the quality of the density measurements being performed.

- Geological Interpretation and Domaining. In complex mineralisation systems, interpretation of the geological framework, mineralisation controls and domains used to constrain grade estimation are critical. This process should be subject to a rigorous QA/QC system such as a formal peer review to ensure a robust and justifiable interpretation is generated. This is not always the case.

- Grade Estimation. Good practice QA/QC involves statistical and visual comparisons of input data with the model data, reconciliation with mine production if appropriate, comparison with previous estimates to assess changes in the new estimate, and comparison against other appropriate estimation approaches. Derisk has sighted numerous examples where some or many of these QA/QC procedures have been neglected.

Inadequacies in QA/QC systems can result in uncertainties that impact a Mineral Resource estimate. The most common ramification is a downgrading of the resource classification e.g., from Measured to Indicated, or from Indicated to Inferred. The worst case is that no Mineral Resource can be estimated.

Derisk considers that QA/QC is a core component of everything a geologist does and it is critical to have adequate QA/QC systems for all data collection types and processes. These systems should evolve as projects progress from early exploration through advanced exploration, feasibility, and mining to ensure they are appropriate and fit‐for‐purpose at each stage.

For more information

Mark Berry (Director and Principal Geologist)

+61 4 0802 9549

[email protected]